.jpg)

The Cooper then raises the barrel inside a metal raising Hope using alternating selected wide and narrow staves to give a good shape to the cask. The steel truss/toasting hoops are fitted to hold the barrel together and form the shape (these are later swapped for metal hoop iron).

The barrel is heated over an open fire, and as the oak begins to steam (water may be added by the Cooper) the staves can be bent without cracking.

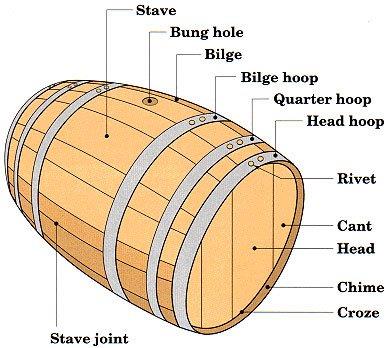

The splayed open end of the cask is then drawn in using a steel cable around the barrel, this tightens and bonds the staves so that another truss hoop can be fitted to the barrel. After toasting on the fire, the inside ends of the staves are each notched with a > shaped notch at both ends on a “crozing” machine.

The next stage is making and fitting of the heads (ends). Between four and six boards would be fastened together on edge by dowel pins to form a wide enough peace to cut out each circular head. A double bevel (basle) is machined to the edge of the head which fits into the “croze” running around the cask at both ends.

Once the heads are fitted the truss hoops are removed and the cask re-hooped with metal/galvanised iron using a hammer & driver (a chisel like tool) to tighten the hoop around the cask (prior to 1800, wooden hops either chestnut or hickory would have been used).

Finally, a bung hole will be bored into a wide stave in the middle of the cask so that the cask can be pressure tested to ensure it is watertight.

Toasting

In order to bend the states into a convex shape the Cooper heats the inside of a newly constructed cast over an open fire, this is toasting. The longer the wood is exposed to the flame, the more toasted/chard it becomes. The degree of toasting is light, medium, heavy and is a highly significant factor influencing the flavours imported to the wine or spirits for example a heavy toasting will give a caramelised taste to wine, whilst a like toasting will give a subtle hint of vanilla.

Ageing

Look plays a big role in wine and spirit making. The colour, flavour, Italian and texture can all be influenced by a oak contact during fermentation or ageing. Wine aged in oak for longer periods of time will therefore have more luck flavours. Cask size is also important since smaller casks will age wine and spirits faster than a larger cask. This is because the small cask has a larger surface area to volume ratio i.e. The smaller the cask the larger surface area of oak is in contact with the wine or spirits; therefore ageing is faster.

New barrel curing/preparation

New barrels need to be cured/swelled tight with water before use. Once you have received your new barrel, before use rinse and flush out with a cold water 2 to 3 times to any debris/sawdust.

To cure, fit the wooden tap into the hole in the head of the barrel and fill the barrel with cold water. Note, it is quite normal for small leaks all trips therefore leave in a place where any leaks will cause no harm, curing usually takes about two days, however it can take up to 4 to 5 days occasionally. Once the drips have stopped, empty the water out of the barrel through the bung hole. Your barrel is now cured and ready for use.

.jpg)